Product Series

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Telephone

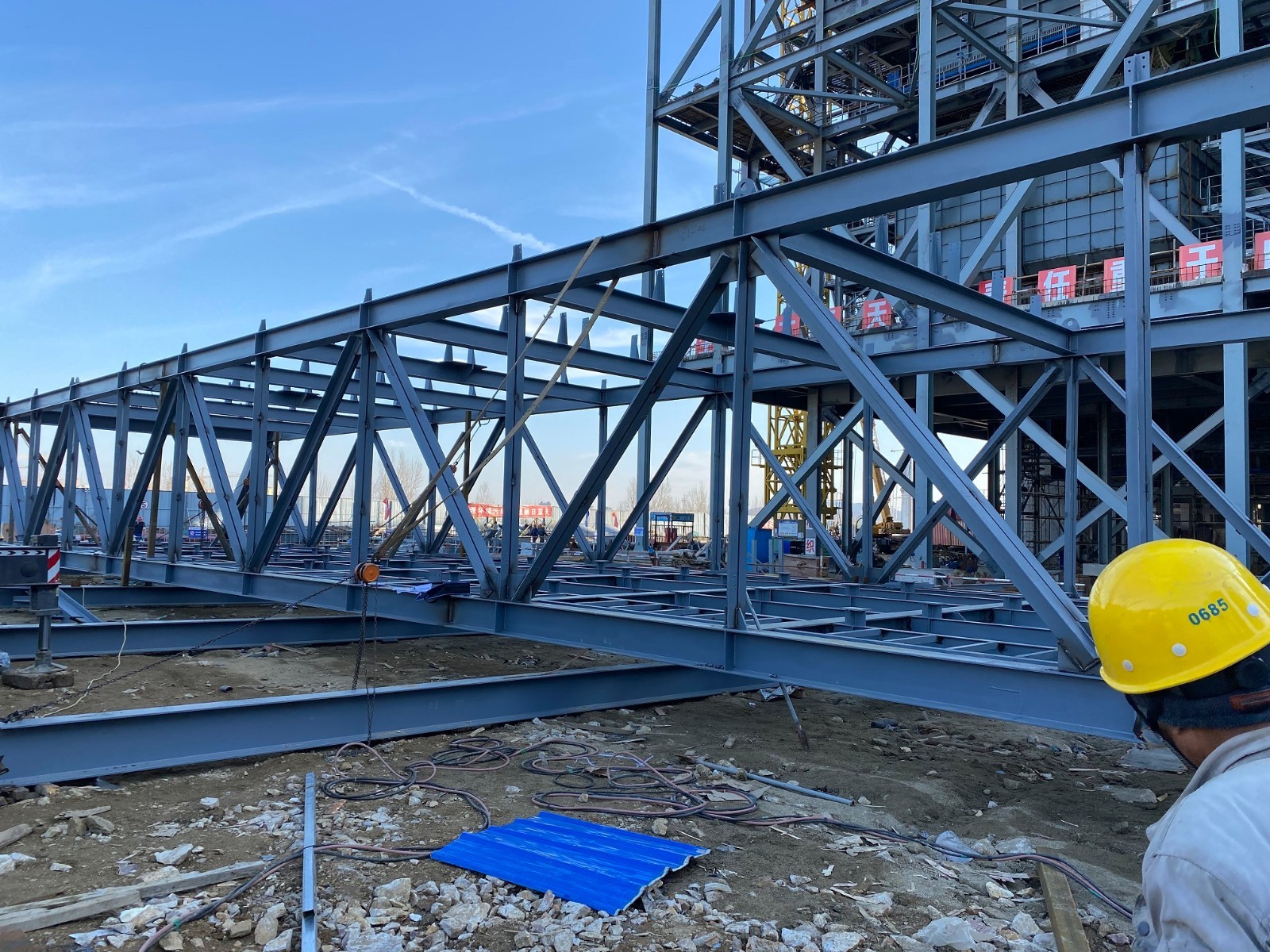

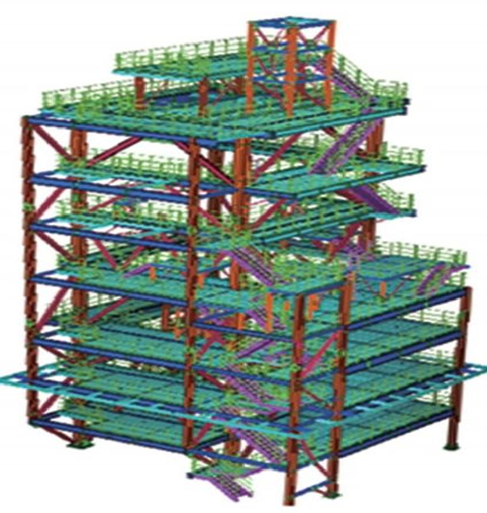

Steel structures are widely used in modern construction, known for their strength, durability, and versatility. Constructed mainly from steel members, such as I - beams, channels, and angles, they can be pre - fabricated off - site, enabling quick and efficient on - site assembly. The high strength - to - weight ratio of steel means that steel structures can bear substantial loads while remaining relatively lightweight. This property makes them suitable for large - span buildings like stadiums, aircraft hangars, and industrial factories. Steel structures offer excellent fire resistance when appropriately protected. Their corrosion resistance can be enhanced through treatments like galvanizing or painting. They also have good seismic performance, being able to withstand the forces generated during earthquakes due to their ductility.In summary, steel structures are a popular choice in construction projects, providing a combination of strength, flexibility, and practicality to meet various architectural and engineering requirements

Steel structures are widely used in modern construction, known for their strength, durability, and versatility. Constructed mainly from steel members, such as I - beams, channels, and angles, they can be pre - fabricated off - site, enabling quick and efficient on - site assembly. The high strength - to - weight ratio of steel means that steel structures can bear substantial loads while remaining relatively lightweight. This property makes them suitable for large - span buildings like stadiums, aircraft hangars, and industrial factories. Steel structures offer excellent fire resistance when appropriately protected. Their corrosion resistance can be enhanced through treatments like galvanizing or painting. They also have good seismic performance, being able to withstand the forces generated during earthquakes due to their ductility.In summary, steel structures are a popular choice in construction projects, providing a combination of strength, flexibility, and practicality to meet various architectural and engineering requirements

Steel structures are widely used in modern construction, known for their strength, durability, and versatility. Constructed mainly from steel members, such as I - beams, channels, and angles, they can be pre - fabricated off - site, enabling quick and efficient on - site assembly. The high strength - to - weight ratio of steel means that steel structures can bear substantial loads while remaining relatively lightweight. This property makes them suitable for large - span buildings like stadiums, aircraft hangars, and industrial factories. Steel structures offer excellent fire resistance when appropriately protected. Their corrosion resistance can be enhanced through treatments like galvanizing or painting. They also have good seismic performance, being able to withstand the forces generated during earthquakes due to their ductility.In summary, steel structures are a popular choice in construction projects, providing a combination of strength, flexibility, and practicality to meet various architectural and engineering requirements

Steel structure of communication tower

Steel structures are widely used in modern construction, known for their strength, durability, and versatility. Constructed mainly from steel members, such as I - beams, channels, and angles, they can be pre - fabricated off - site, enabling quick and efficient on - site assembly. The high strength - to - weight ratio of steel means that steel structures can bear substantial loads while remaining relatively lightweight. This property makes them suitable for large - span buildings like stadiums, aircraft hangars, and industrial factories. Steel structures offer excellent fire resistance when appropriately protected. Their corrosion resistance can be enhanced through treatments like galvanizing or painting. They also have good seismic performance, being able to withstand the forces generated during earthquakes due to their ductility.In summary, steel structures are a popular choice in construction projects, providing a combination of strength, flexibility, and practicality to meet various architectural and engineering requirements

Steel structures are widely used in modern construction, known for their strength, durability, and versatility. Constructed mainly from steel members, such as I - beams, channels, and angles, they can be pre - fabricated off - site, enabling quick and efficient on - site assembly. The high strength - to - weight ratio of steel means that steel structures can bear substantial loads while remaining relatively lightweight. This property makes them suitable for large - span buildings like stadiums, aircraft hangars, and industrial factories. Steel structures offer excellent fire resistance when appropriately protected. Their corrosion resistance can be enhanced through treatments like galvanizing or painting. They also have good seismic performance, being able to withstand the forces generated during earthquakes due to their ductility.In summary, steel structures are a popular choice in construction projects, providing a combination of strength, flexibility, and practicality to meet various architectural and engineering requirements

A custom - built lighthouse is a highly specialized structure designed to meet specific navigational, environmental, and operational requirements. **Location and Function - Based Classification** The lighthouse type varies according to its location and function. For instance, an offshore navigation lighthouse is strategically positioned in the open sea to guide vessels over long distances, while an inland waterway guiding lighthouse is tailored for rivers and canals. **Physical Dimensions** It has a well - defined set of physical dimensions. The overall height, which can reach up to 50 meters, spans from the lowest part of the foundation to the top of the light - emitting structure. The base diameter of 8 meters and upper structure diameter of 3 meters contribute to its stability and the proper placement of the light source. **Construction Materials** A combination of materials is used in its construction. The main body is often made of reinforced concrete for its strength and durability, while stainless - steel fixtures are employed for their corrosion - resistant properties. **Lighting System** The lighting system is a crucial aspect. The main lamp, with a power of 2000 W, provides high - brightness illumination for long - distance visibility in clear weather, reaching up to 25 nautical miles. Additionally, an auxiliary lamp with 500 W power serves as a backup or for supplementary functions. The flash pattern, like a repeated sequence of long - short - short flashes, is unique for identification, occurring at a frequency of 40 times per minute. In adverse weather such as fog, it can still be visible up to 10 nautical miles. The light color can be multi - colored, with red for danger indication and white for general navigation, and the light beam angle of 120° determines its coverage area. **Foundation and Structural Integrity** The foundation is designed to ensure stability. With a depth of 6 meters, it can be of a specific type like a pile foundation. To withstand various natural forces, the lighthouse has an anti - corrosion treatment consisting of an epoxy primer, zinc - rich intermediate coat, and polyurethane topcoat. It can resist strong winds up to Beaufort 12 and seismic activity of seismic intensity 8 according to the China standard. A comprehensive lightning protection system with multiple lightning rods and a low - resistance grounding system safeguards it from lightning strikes. **Monitoring and Emergency Provisions** It is equipped with remote monitoring capabilities, allowing for the tracking of parameters such as lamp status, power consumption, and wind speed around the lighthouse. In case of a main power failure, a 50 - kW diesel - powered generator serves as an emergency power supply. In summary, a custom - built lighthouse is a sophisticated and resilient structure that combines precise design, advanced technology, and robust construction to fulfill its vital navigational and safety functions in diverse environments.

I - beams, also known as H - beams, are crucial structural steel products widely utilized in construction and various industrial applications. The cross - sectional shape, resembling the letter "I", is a distinct feature. This shape endows I - beams with high strength and excellent load - bearing capacity. The size of I - beams is characterized by parameters like height, flange width, and web thickness. These dimensions vary according to different engineering requirements, from small - scale projects with relatively thin and short I - beams to large - scale infrastructure with massive ones. In terms of mechanical properties, I - beams generally have high tensile and compressive strengths. They can withstand significant vertical and horizontal loads, making them suitable for use in building frameworks, bridges, and industrial equipment supports. I - beams are typically made from carbon steel or alloy steel. The choice of material determines their corrosion resistance, hardness, and other properties. For some outdoor or corrosive - environment applications, corrosion - resistant coatings may be applied to extend their service life. Overall, due to their unique shape, diverse sizes, and good mechanical properties, I - beams play an essential role in modern construction and industrial projects.

Angle steel, also called L - steel, is a widely - used steel product in construction, manufacturing, and various other industries. It has a distinctive L - shaped cross - section, which gives it good structural stability and load - bearing capabilities. The size of angle steel is defined by leg lengths and thickness. The leg lengths can vary significantly, from small values suitable for light - duty applications to larger ones for more robust structures. Thickness is also precisely controlled according to different requirements. In terms of mechanical properties, angle steel typically has high strength, enabling it to withstand various types of stress. Its tensile strength allows it to resist stretching forces, while its compressive strength helps it endure squeezing loads. This makes it suitable for applications such as bracing structures in buildings, framework components in machinery, and supports in industrial equipment. Angle steel is usually made from carbon steel. Some special - purpose angle steel may be made from alloy steel to enhance specific properties like corrosion resistance or hardness. In outdoor or corrosive environments, anti - corrosion treatments like painting or galvanizing are often applied to extend its service life. Overall, due to its unique shape, diverse sizes, and good mechanical properties, angle steel plays an important role in a wide range of projects.

Channel steel, a commonly - used structural steel product, plays a vital role in construction, manufacturing, and numerous other industrial sectors. The cross - sectional shape of channel steel, resembling a "U" or "C", is its most prominent feature. This unique shape provides it with good load - bearing capacity, especially for applications where lateral support and stability are required. The size of channel steel is typically denoted by parameters such as height, leg width, and web thickness. These dimensions can vary greatly according to different engineering needs. For example, in small - scale construction projects, smaller - sized channel steel with a lower height and thinner web may be used, while large - scale industrial structures often require channel steel with larger dimensions. Regarding mechanical properties, channel steel generally has high tensile and compressive strengths. It can endure significant vertical and horizontal loads, making it suitable for constructing frameworks, supporting structures, and bracing systems. In addition, its yield strength is carefully designed to ensure that it can maintain elastic deformation within the normal working stress range, preventing excessive plastic deformation. Channel steel is usually made from carbon steel. In some cases, alloy steel may be used to enhance specific properties. To improve its corrosion resistance, especially in outdoor or corrosive environments, treatments like painting, galvanizing, or applying anti - corrosion coatings are often carried out. Overall, due to its distinctive cross - sectional shape, diverse size options, and favorable mechanical properties, channel steel is an essential material in a wide variety of projects across different industries.

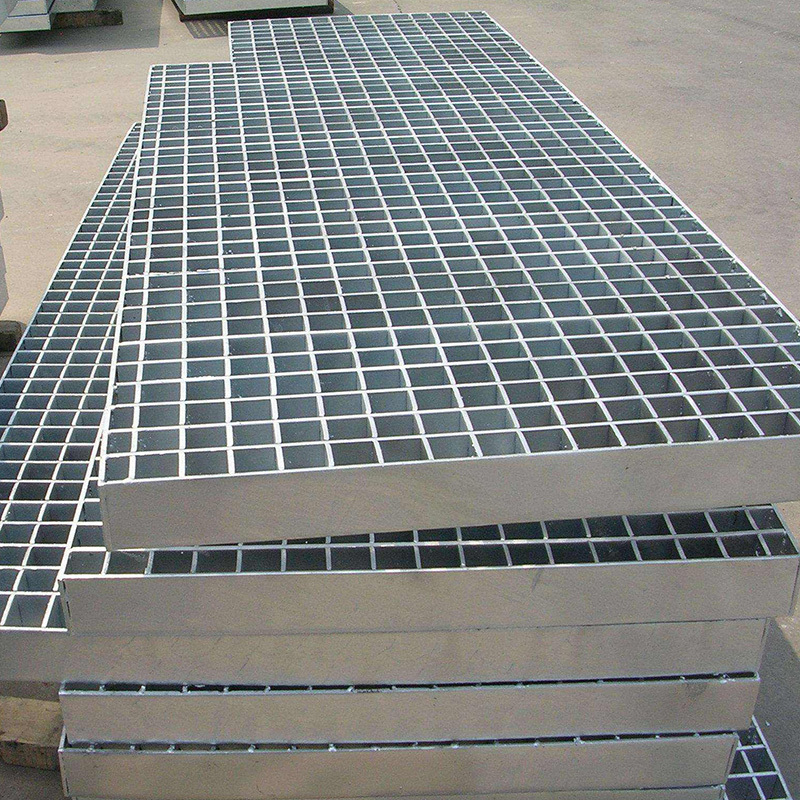

Steel grating is a highly practical and widely - used material in various industries, especially in construction, industrial flooring, and infrastructure projects. The structure of steel grating is composed of bearing bars and cross - bars. The bearing bars are responsible for bearing the main load, and their size and spacing are crucial parameters. They are usually made of high - strength steel, with thicknesses and widths varying according to different load - bearing requirements. The cross - bars, on the other hand, are evenly spaced and welded or locked to the bearing bars to form a stable grid - like structure. The opening size of the steel grating is another important feature. It determines the amount of light, air, and liquid that can pass through, as well as the ability to prevent objects from falling through. Different applications may require different opening sizes, from small openings for safety - critical areas to larger ones for drainage - intensive environments. Steel grating offers excellent load - bearing capacity. It can withstand heavy loads, whether they are uniformly distributed or concentrated, due to its robust structure. The load - bearing capacity is determined by factors such as the material of the bars, their size, and the manufacturing process. Corrosion resistance is also a significant advantage of steel grating. Through surface treatments like hot - dip galvanizing, painting, or powder coating, the steel grating can resist corrosion in various environments, including humid, chemical - laden, or outdoor settings. This extends its service life and reduces maintenance costs. In addition, steel grating is known for its good anti - slip properties. The surface of the grating can be designed with serrations or other anti - slip patterns, ensuring safety in areas where people may walk or operate machinery. Overall, due to its unique structure, high load - bearing capacity, corrosion resistance, and anti - slip properties, steel grating is an essential component in numerous construction and industrial applications.

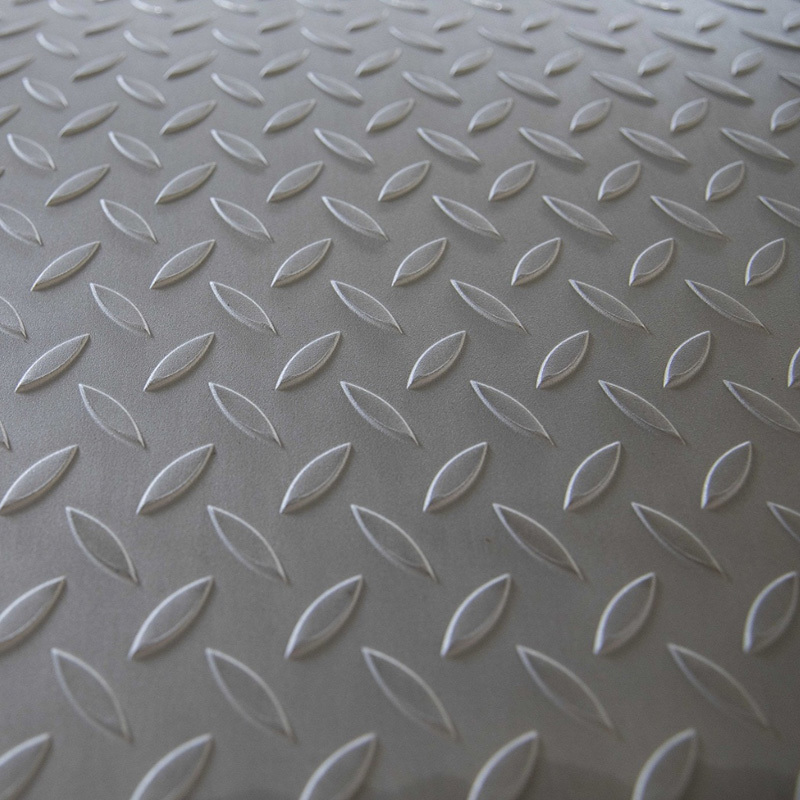

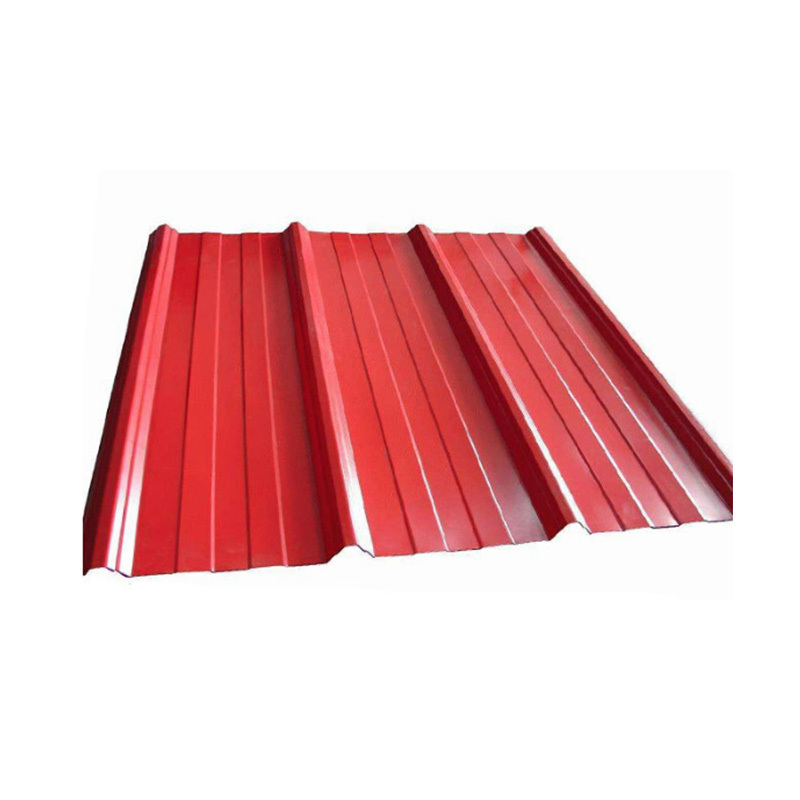

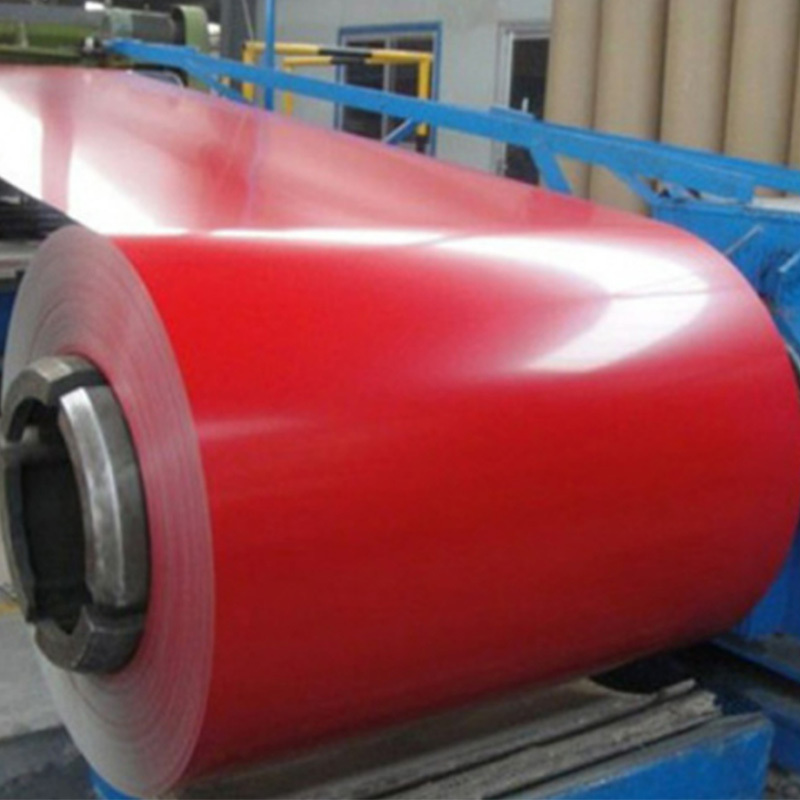

The printed color coated steel plate is available in a variety of colors and patterns to make the building look great.

Color Steel Roofing Sheet is a galvanized color-coated steel material. The coated steel sheet is subjected to surface chemical treatment, and then coating is applied and then baked.

Color Coated Plate can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

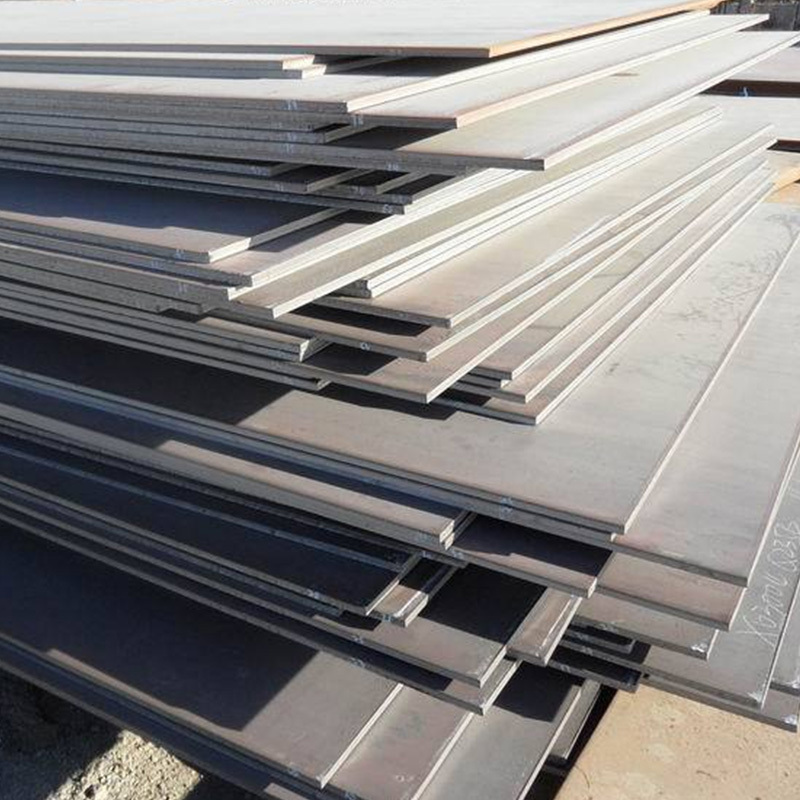

Carbon steel plates are essential construction and industrial materials. The grade designation, like S235JR in European standards, is crucial as it determines the fundamental mechanical and chemical properties. The actual thickness may deviate slightly from the nominal value, for example, 8.1 mm for a nominal 8 - mm plate. Straightness deviation, limited to ≤ 2 mm/m, affects the plate's flatness in large - scale applications. Shear strength, reaching up to 250 MPa, enables the plate to withstand cutting or tearing forces. Fatigue strength, such as 180 MPa at 10^6 cycles, is relevant for applications with repetitive stress. The corrosion rate in a specific environment, like 0.05 mm/year in a 5% NaCl salt - fog environment, indicates its resistance to corrosion. Carbon content, ranging from 0.18 - 0.25%, significantly influences the plate's hardness, strength, and ductility. Sulfur and phosphorus content are strictly limited (S ≤ 0.045, P ≤ 0.045) to maintain quality. Heat treatment, such as annealing, quenching, or tempering, is used to achieve desired mechanical properties. The coating adhesion strength, with a minimum of ≥ 5 N/mm², ensures the quality of the coating - substrate bond. Overall, these parameters comprehensively define the performance and quality of carbon steel plates, making them suitable for a wide range of applications.

Aluminum coils are highly versatile materials widely used across various industries. They are valued for their unique combination of properties. The alloy type of aluminum coils is like the “identity card,” which is specified according to international or industry - specific standards. Different alloy types, such as 1100, 3003, or 6061, determine the fundamental mechanical and chemical characteristics of the coil. For instance, the 6061 alloy is known for its good strength - to - weight ratio and excellent corrosion resistance. The thickness of aluminum coils is a crucial parameter. It can vary significantly based on the intended application, ranging from thin foils for packaging, which might be as thin as 0.05 mm, to thicker gauges for construction or automotive applications, like 1 - 3 mm. Precision in thickness control is vital, as it affects the coil's performance in different processes. Width is another key dimension. Aluminum coils can be manufactured in a wide range of widths, from narrow strips for specialized applications to broad widths for large - scale production. A common width for general - purpose coils could be around 1000 - 1500 mm. Tensile strength is an important mechanical property. It indicates the maximum stress the aluminum coil can withstand during stretching without breaking. For example, some common alloys might have a tensile strength in the range of 100 - 300 MPa. This property is crucial for applications where the material needs to endure mechanical stress. Elongation, expressed as a percentage, shows the ability of the aluminum coil to deform plastically before breaking. A higher elongation percentage, say 10 - 20% for certain alloys, implies better formability, making it easier to shape into various products. Surface finish also plays a significant role. It can range from a mill - finish, which has a natural texture from the manufacturing process, to a highly polished or pre - painted finish. The surface finish affects not only the aesthetic appearance but also the corrosion resistance and adhesion properties for further processing, such as coating or laminating. Aluminum coils are also known for their good electrical conductivity, making them suitable for electrical applications. Additionally, their low density compared to many other metals makes them an ideal choice when weight reduction is a priority, such as in the aerospace and automotive industries. Overall, these properties make aluminum coils an essential material, meeting the diverse needs of different sectors.

Galvanized steel pipe has a welded steel pipe with a hot dip or electro galvanized layer on the surface.

It is suitable for stress and pressure parts, as well as steam, water, gas and air pipelines for general purposes.

Stainless steel pipe is the most common type of steel pipe across the globe for a number of its characteristics.

Alloy tubes are widely used in numerous industrial fields, highly regarded for their unique combination of properties. The alloy composition of alloy tubes is a key feature, precisely formulated according to international or industry standards. Different alloy combinations, such as chromium - molybdenum alloys and nickel - based alloys, determine the fundamental mechanical and chemical properties of the tubes. For instance, chromium - molybdenum alloy tubes are renowned for their excellent strength and corrosion resistance in high - temperature and high - pressure environments. Outer diameter and wall thickness are important dimensional parameters of alloy tubes. The outer diameter varies in multiple specifications depending on the specific application scenarios. It can range from a small diameter of just a few millimeters for precision instruments to a large diameter of hundreds of millimeters for large - scale industrial pipelines. The wall thickness also needs to be precisely controlled to ensure the safety and reliability of the alloy tubes when withstanding internal pressure and external loads. Tensile strength is an indicator measuring the ability of alloy tubes to withstand tensile forces without breaking. For many common alloy tubes, the tensile strength can range from several hundred megapascals to over a thousand megapascals. This property is crucial in applications that require the tube to endure significant pulling forces, such as the transportation pipelines in the oil drilling industry. Yield strength indicates the stress value at which the alloy tube begins to undergo plastic deformation. An appropriate yield strength can ensure that the alloy tube remains elastic within the working stress range and avoids excessive deformation. Corrosion resistance is also one of the important properties of alloy tubes. Different alloy compositions endow them with the ability to resist corrosion in various corrosive environments. For example, in media containing acids, alkalis, or salts, certain alloy tubes can effectively slow down the corrosion rate and extend their service life. In addition, the fatigue resistance of alloy tubes cannot be overlooked. In some applications where cyclic stress is endured, such as the exhaust pipes of engines, alloy tubes need to have good fatigue strength to withstand long - term alternating loads without fatigue fracture. Thanks to their unique alloy composition, precise dimensional specifications, and excellent mechanical and chemical properties, alloy tubes play an indispensable role in many fields, including petrochemical, power, aerospace, and more.